HELIFIL

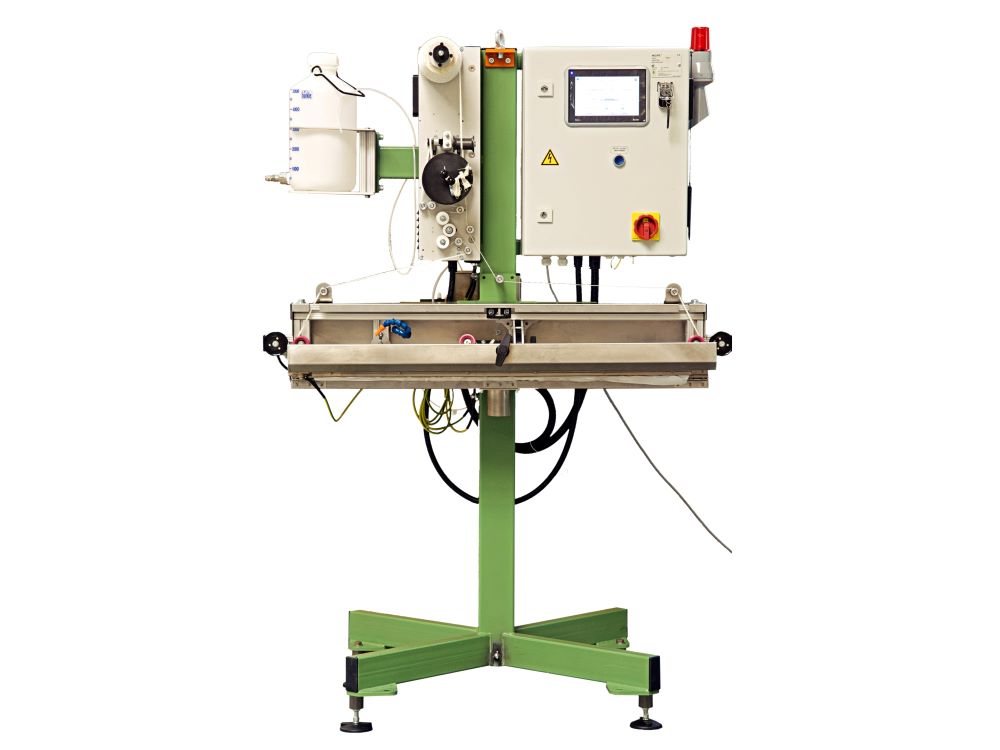

HELIFIL HELIFIL is the little brother of HELICORD® using the same basic principle. It was designed specifically to meet the needs of small diameter wire production lines, where limited space is available and low forces are sufficient. HELIFIL machines therefore are small units suitable for friction forces of up to 30N only.