HELILUB®

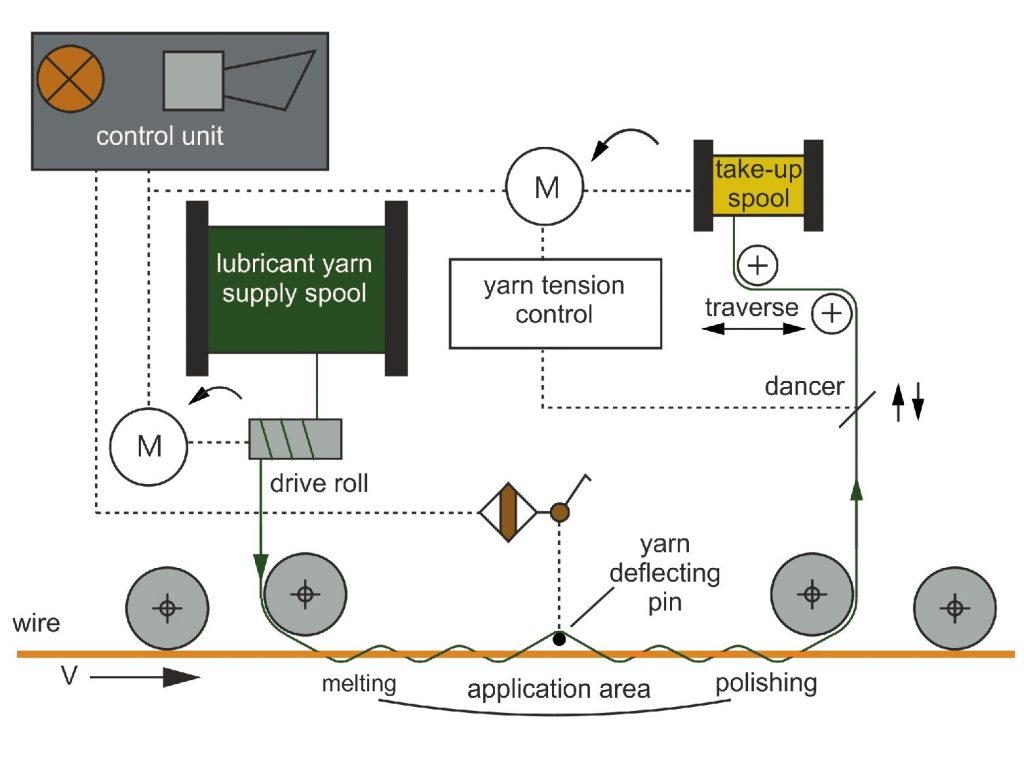

The HELILUB® process applies lubricant to the surface of magnet wire using an impregnated cellulose yarn, which wraps around the wire multiple times and moves slowly in the opposite direction of the wire run. This ensures consistent coating and precise control of the lubricant amount, improving wire performance.

The calibration of the yarn and the yarn tension, together with the speed difference between yarn and wire, control the amount of lubricant applied and polished onto the wire surface. As a result, the wire receives a consistent and precise layer of lubricant. After the enameling oven, the wire temperature melts the lubricant in the lubricating yarn, and the applied quantity can be calculated by comparing the yarn weight per meter before and after the process.

HELILUB® handles a wide variety of lubricants, including high-melting or insoluble types and in addition, it allows easy adjustment of the applied quantity. It is suitable for warm, cold, fine, and ultra-fine wire applications.

Advantages:

- Exact lubricant dosage

- Easy calculation of applied lubricant amount

- Simple and precise process control

- Lowest coefficient of friction even at high enameling speeds